Revolutionizing Warehouse Operations

Our Intelligent Warehouse Management System (IWMS) delivers the same operational efficiency as expensive AGV (Automated Guided Vehicle) and TGV (Tugger Guided Vehicle) systems at a fraction of the cost. By intelligently guiding forklift drivers through optimized workflows, we eliminate the need for costly automation while maintaining peak performance.

The Smart Alternative

AGV/TGV Systems

High capital investment, complex infrastructure, and extensive maintenance requirements. Automated vehicles navigate independently but come with significant upfront and operational costs.

IWMS-Guided Operations

Utilizes existing forklifts with intelligent guidance systems. The driver follows system instructions, eliminating decision-making delays while maintaining flexibility and dramatically reducing costs.

Why Choose IWMS?

Cost-Effective

Achieve AGV-level results at 10-20% of the cost. No massive infrastructure investment required.

Color-Coded Simplicity

Intuitive interface based on color coding makes it accessible to operators of any education level.

Rapid Implementation

Operators can be fully trained in less than one week, minimizing downtime during deployment.

Guided Precision

Drivers follow system instructions, eliminating decision-making errors and optimizing every movement.

Flexible Adaptation

Works with existing equipment. Easy to scale and modify as your operations evolve.

Real-Time Intelligence

Smart routing, inventory tracking, and performance analytics built into every operation.

Security Alarm System

Built-in alarm triggers on any wrong transaction. Security protocols prevent forklift exit until discrepancies are resolved.

Error Prevention

Zero tolerance for mistakes. The system immediately detects and alerts on incorrect operations, ensuring 100% accuracy.

Key System Components

Smart Pallets

Hand Held

Ground Pin Location

Rack Pin Location

Forklift

Gate

Intuitive Interface Design

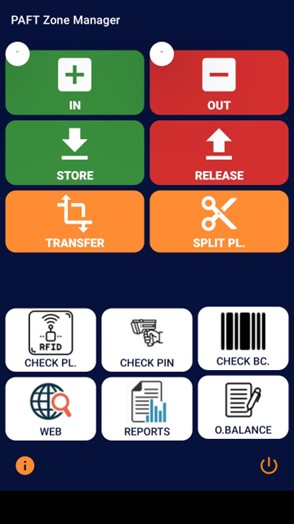

PAFT Zone Manager

Our streamlined interface eliminates complexity. Unlike traditional WMS systems that require extensive training and technical expertise, IWMS uses clear visual indicators and color-coded commands. Operators can immediately understand IN/OUT operations, STORE/RELEASE actions, and TRANSFER protocols without confusion.

The Bottom Line

IWMS bridges the gap between manual operations and full automation. While other systems are complicated, expensive, and require highly educated users, our solution is accessible, affordable, and delivers comparable results. The forklift driver becomes an executor of intelligent decisions made by the system—eliminating errors, improving efficiency, and maximizing warehouse productivity without breaking the bank.

Security First: Our integrated alarm system ensures complete accountability. Any incorrect transaction immediately triggers an alert, and security protocols prevent the forklift from leaving the facility until the issue is resolved. This creates a zero-error environment where mistakes are caught instantly, protecting your inventory and maintaining operational integrity.